Shear stress in Beam - Strength of Material

CIVIL ENGINEERING QUESTIONS

|

Question-Answer civil engineering study

|

Previous year civil engineering questions related to strength of material (SOM) subject topic shear stress in Beam asked in UPSC ESE examination.

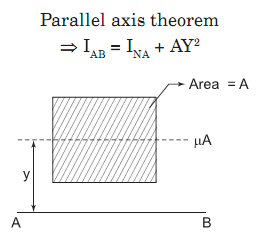

Shear Force per unit length = `H/x` = `(VAy)/I`

Shear stress at the level y from N.A. = q = `(VAy)/Ib`

Shear stress in Rectangular beam

|

| Shear stress in rectangular beam |

Shear stress in I section

|

| shear stress in I section |

Shear stress in circular section

|

| shear stress in circular section |

Shear stress in triangular section

|

Shear stress in triangular section |

Shear stress in Quadrilateral section about diagonal

|

| Shear stress in Quadrilateral section about diagonal |