Masonry and Tunnel

Related to Brick and Stones

Stone Masonry

Stone masonry can be classified into two types:

- Rubble Masonry & Ashlar Masonry

Rubble Masonry:

- The type of stone masonry in which either undressed or roughly dressed stone are laid in a suitable mortar is called rubble masonry. In this masonry the joints are not of uniform thickness.

Ashlar Masonry:

- It is the type of stone masonry in which finely dressed stones are laid in cement or lime mortar is known as ashlars masonry. In this masonry are the courses are of uniform height, all the joints are regular, thin and have uniform thickness. This type of masonry is much costly as it requires dressing of stones.

Three types of Rubble Masonry are as follows:

Un-coursed Random Rubble Masonry:

- The random rubble masonry in which stones are laid without forming courses is known as un-coursed random rubble masonry. This is the roughest and cheapest type of masonry and is of varying appearance.

- It is used for construction of walls of low height in case of ordinary buildings.

Coursed Random Rubble Masonry:

- The random rubble masonry in which stones are laid in layers of equal height is called random rubble masonry. In this masonry, the stones are laid in somewhat level courses. Headers of one coursed height are placed at certain intervals. The stones are hammer dressed. CRRM is used for construction of residential buildings, boundary walls etc.

Squared Rubble Masonry:

- The rubble masonry in which the face stones are squared on all joints and beds by hammer dressing or chisel dressing before their actual laying, is called squared rubble masonry.

There are two types of squared rubble masonry:

Coursed Square Rubble Masonry:

- The square rubble masonry in which chisel dressed stones laid in courses is called coarse square rubble masonry. It is used for construction of public buildings, hospitals, schools, markets, modern residential buildings etc. and in hilly areas where good quality of stone is easily available.

Un-coursed square rubble masonry:

- The squared rubble in masonry which hammer dressed stones are laid without making courses is called un-coursed square rubble masonry. It consists of stones which are squared on all joints and beds by hammer dressing. All the stones to be laid are of different sizes. It is used for construction of ordinary buildings in hilly areas where a good variety of stones are cheaply available.

Dry rubble masonry:

- The rubble masonry in which stones are laid without using any mortar is called dry rubble masonry or sometimes shortly as "dry stones". It is an ordinary masonry and is recommended for constructing walls of height not more than 6 m.

Quoins

- 1. Quoins are large rectangular blocks of masonry or brick that are built into the corners of a wall and is normally 90o to the horizontal.

- 2. They can be used as a load-bearing feature to provide strength and weather protection, but also for aesthetic purposes to add detail and accentuate the outside corners of a building.

- 3. Quoins are external cornerstones at the edges of stone or brick buildings.

King closer:

- If a brick is cut in such a way that the width of one end becomes half that of a full brick, while the width at the other end is equal to the full width, then it is called as king closer.

- It is obtained by cutting out a triangular portion of the brick between the centre of one end (width side) and the centre of the other end (lay side).

Queen closer:

- When a brick is cut along its length, making it two equal halves then it is called queen closer.

- Squint brick:

- They are cut on one corner at an angle of other than 90 degrees. They are required for giving shape to an exterior or interior corner in a wall.

Thickness of Damp Proof Course D.P.C.

- A cement concrete layer in the proportion 1: 2: 4 is generally provided at the plinth level to work as a damp-proofing course.

- The depth of the cement concrete layer varies from 40 mm to 150 mm. It stops the rise of water by capillary action and it is found to be effective at places where the damp is not excessive.

- Here 4 cm, 5 cm, and 6 cm all are the correct answer for the question as they lie in the desirable range of 4 cm to 15 cm of plinth thickness. However, 4 cm distinct as minimum plinth thickness and hence it is the most appropriate option.

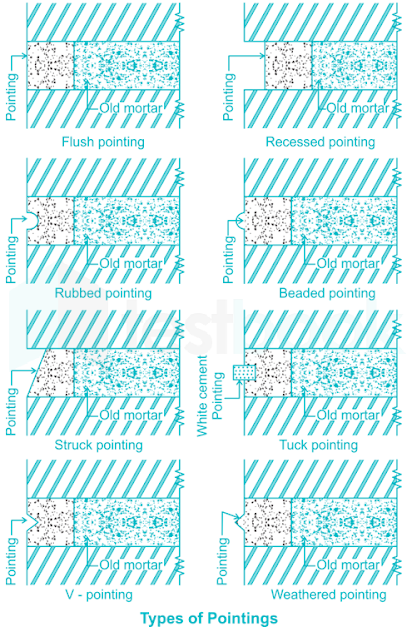

Pointing

Struck Pointing:

Recessed Pointing:

Beaded Pointing:

Tuck Pointing:

Weathered Pointing:

|

| Types of Pointing |

Thickness of Plastering

Note:

Tunnel

- a) Tunnels are more economical than open cuts beyond certain depths.

- b) Tunnels avoid disturbing or interfering with surface life and traffic during construction.

- c) Tunnels prove to be cheaper than bridges or open cuts to carry public utility services like water, sewer, gas, electricity and telephone lines.

- d) There is an overall reduction in cost because of shortening the distance as compared to bridges or open cuts.

- e) Tunnels avoid interference with surface and air rights.

- f) Its maintenance cost is low.

- a) The initial cost of construction of a tunnel is high as compared to an open cut.

- b) It is necessary to have skilled labour and technical supervision of high order for the construction of a tunnel.

- c) It takes a long time for the successful completion of a tunnel under normal conditions.

- d) The construction of the tunnel requires specialized and sophisticated equipment.

- i) Full face method

- ii) Heading and bench Method

- iii) Cantilever car dump Method

- iv) Drift system

- v) Pilot tunnel Method

- i) Forepoling Method

- ii) Needle beam Method

- iii) Five-piece set Method

- iv) Liner plates Method

- v) Casing Method

- vi) Square set and lagging Method

- vii) Horse cups Method

- Tunnel jacking is the process of making a tunnel in already existing bodies such as road and railway area

- These types of tunnels are partly or wholly under water.

- Tunnel lining is the wall of the tunnel.

- It is usually in the form of a ring of a precast concrete segment.

- A shield tunnelling is a protective structure and trailing support mechanism.

- It is a method of providing additional support to the drilled mine.

Methods of tunnelling in hard rock | Methods of tunnelling in soft soil |

Drift Method | Fore-poling method |

Heading and benching method | Needle beam method |

Full face method | Army method or case method |

Cantilever car dump method | American method |

Pilot tunnel method | English method |

Perimeter method or German method | Belgian method |

| Shied tunnelling method |

| Linear plates method |

- The circular section of a tunnel offers greater resistance to external pressure caused by water, water-bearing soils or soft grounds.

- i) It is the best theoretical section for resisting internal and external section.

- ii) It provides the greatest cross-sectional area for the least perimeter.

- iii) It is the best suited for noncohesive soils.

- iv) It is most suitable for sewers and water carrying purposes.

- i) Not suitable for roadways or railways as more filling is required.

- ii) The shape is more difficult for the concrete lining.

California Bearing Ratio (CBR) test:

Types of Explosive

Type of Explosive | Suitability |

Blasting Powder | In large quarrying blocks |

Dynamite | Small boreholes and quarries |

Cordite and Gelignite | Under water |

Lithofracteor | Tunnels |

very nice

ReplyDelete